Wholistic MRO: 4 Constructive Strategies for Managing MRO in the Aviation Industry

Published :

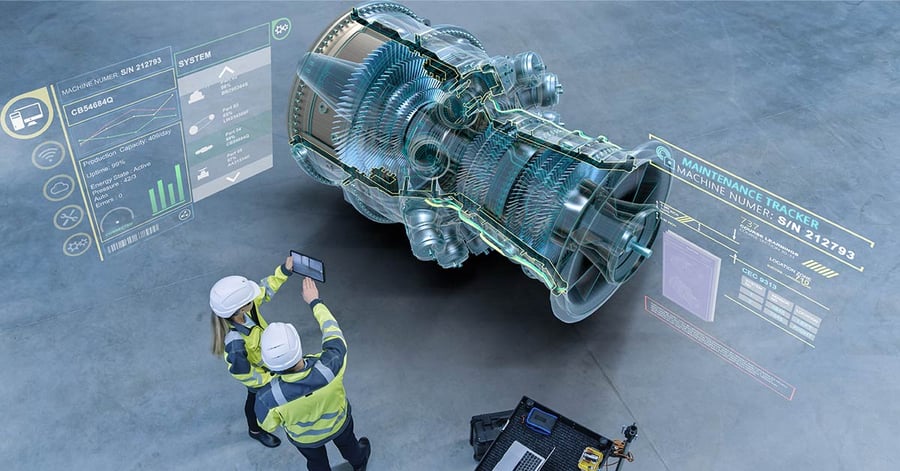

With technology evolving at a tremendous pace and aviation assets becoming more and more complex, it has become challenging for MRO providers of all types and sizes to manage and perform their operations effectively and efficiently. Antiquated and disparate legacy systems, data overload, and siloed processes make it difficult to integrate end-to-end MRO aviation processes such as maintenance scheduling, forecasting, inventory management, quality assurance, and finance.

Despite the challenges that MROs face, a few industry leaders have adopted forward-thinking approaches to doing business in a digital era. One of the highest poles in the tent of transformation for most MROs is a robust and tightly integrated aviation maintenance and engineering software platform that enables standardization, automation, a significant reduction in manual effort and does so with best-in-class quality. As the industry continues to rebound from the pandemic and we move further into the 21st century, digital transformation is becoming less of a side interest or novelty and more of a necessity and central strategy to remain competitive as an Aviation MRO that wants to be known for quality service and quick turnaround times. But happy customers and fast TATs are just the icing on the cake, as tangible business benefits such as reduced overhead and optimized inventory are just some of many that can be achieved.

As more MROs begin to take a closer look at their end-to-end processes and explore ways to improve efficiencies and create positive impacts on the bottom line, it has become clear that viewing the entire business in a wholistic manner where data and information flows seamlessly under one ecosystem is proving to be the most practical, viable, and effective solution for dealing with dynamic aviation requirements. In such integrated solutions, technology, people (including vendors, OEMs, and third-party service providers) and processes are intricately connected. Every phase of the entire MRO aviation process, from customer inquiries and the receipt of assets, to invoicing and accounts receivable can be well-coordinated and finely tuned to achieve optimal results at reduced cost and effort by considering the following strategies.

Collaboration between customers, front office sales teams, and technicians and engineers on the shop floor can be a key differentiator when it comes to the end goal of achieving an optimal TAT. This is due to the exchange of information and insights that can occur that would ultimately improve the work scoping process. Unfortunately, it can be difficult to facilitate this level collaboration without the right tools in place. In any business, there are many critical transactions that happen on an ad-hoc basis such as emails, phone calls, etc. This can create drag on TAT and efficiency. Not only that, but a certain amount of intelligence and automation is lost when this occurs.

One way to reduce the effects of information escaping from the confines of a single platform is by enabling a portal that would serve as an interactive medium between the customer and the Aviation MRO. Additional approvals that may be required can be immediately relayed to the customer. Customers can see status of their assets at any time. Any and all communication that needs to happen between the customer and the MRO can be tracked directly against the work being performed. One other way to enable collaboration within the MRO process is by empowering technicians with the latest mobile applications with built-in collaborative features such as audio, video, and text chat. Investments into solutions like these can significantly reduce transaction cost and time and improve TAT.

When information systems are disparate and other processes are poorly aligned, complications and complexities become apparent. Not only should the MRO invest in an advanced aviation ERP platform that can keep up with these complexities, but it should also pay close attention to invest in one that can leverage AI (artificial intelligence) and ML (machine learning) to assist users in making quick decisions. One use case for this is the ability to differentiate between non-routine and routine tasks and the differences in cost and procedures that pertain to each. Over time as data is collected and analyzed, a good aviation ERP with the latest AI/ML technology will begin to enable predictive maintenance and automate material allocation.

Another way that maintenance processes can be streamlined is by eliminating hard copy handoffs. By transitioning to a digital maintenance and engineering solution, MROs can begin to realize paperless operations which reduce waste and take away room for human error. Also, by taking a step back and analyzing entire processes from a lean or agile perspective, the MRO can create the proper workflows within their application to enable optimal efficiency.

Inventory management has been a problem for many businesses across various industries. The most pertinent problems include high inventory returns, poor or no measurement of service levels and fill rates, ongoing inventory obsolescence, and excesses. It is important to plan for every part (PFEP), instead of applying a common strategy across all operations. In addition to deploying part replenishment and segmentation strategies, it is essential for MROs to maintain comprehensive information on every part in their inventory. With details such as part attributes, metrics, demand statistics, and inventory targets, the MRO can develop specific strategies for every part. Furthermore, logic can be built within a well-defined ERP to automate many of the manual inventory processes that tend to slow down production.

When it comes to demand forecasting, MROs have typically relied on demand history as a precedent to forecast future demand. However, this is an unreliable predictor of future demand as it does not take into consideration the changing dynamics of operations on the shop floor. To properly forecast demand, tools with advanced algorithms that can perform “what if” and other analyses should be deployed. Aside from advanced technology, taking the time to develop sound sourcing strategies where the best suppliers for any given scenario are identified can have a significant positive impact on lead times and quality.

Assuming the MRO has competitive analytical capability and a concrete decision-making process in place, it can realize significant cost advantages by outsourcing some of its processes. Outsourcing services can be highly advantageous for the MRO because it gives them an edge in coping with the fierce competition from specialized vendors and allows it to focus on its core strengths. But making effective choices when it comes to outsourcing requires a couple of different inputs to determine the optimal course of action.

One critical input is the historical data captured from previous jobs. What was the time and material cost? What types of work was outsourced? What was the cost and turnaround time for the outsourced work? By leveraging all these data elements, total cost of ownership can be determined. Aside from total cost of ownership, the MRO should create a competitive bidding process to ensure that the best terms are negotiated. In some scenarios it may be more costly to go with an incumbent service provider and unless proper market analysis is performed, any cost savings which would occur by choosing a different vendor will go unrealized. The combination of analyzing historical trends in data and while creating competition amongst 3rd party vendors will enable quicker outsourcing decisions and reduce cost and TAT.

Deploying these 4 strategies to achieve technically advanced and streamlined aviation MRO processes can result in enhanced reliability, increased speed, and reduced costs. While each of the 4 strategies have different impacts at various steps in the process, when combined, they can produce optimal results by making the MRO operations more automated and efficient. As demand for MRO services rebounds and more players enter the market, digital and business process transformation becomes paramount in delivering a competitive edge to any MRO shop.

Enterprise asset management (EAM) involves the management of mission critical assets of an organization throughout each asset's lifecycle. EAM is used to plan, optimize, execute, and track the needed maintenance activities with the associated priorities, skills, materials, tools, and information. The aim is to optimize the quality and utilization of assets throughout their lifecycle, increase productive uptime and reduce operational costs.

Enterprise asset management (EAM) involves the management of the maintenance of physical assets of an organization throughout each asset's lifecycle. EAM is used to plan, optimize, execute, and track the needed maintenance activities with the associated priorities, skills, materials, tools, and information.

The software helps in effective maintenance of assets through preventive, predictive, shutdown and breakdown maintenance strategies. The system also helps enterprises mitigate equipment risks by enhanced safety standards. The streamlined operations and improved asset performance helps organizations increase their investment effectiveness.

EAM is important because it helps organizations track, assess, manage and optimize asset quality and reliability. Asset intensive Organizations have hundreds, thousands, even millions of assets which needs to be maintained to maximize / optimize life of these assets to increase the return on investment.

The key features of effective EAM are:

Asset Intensive companies under the following Industries :

Contact us for a meeting and schedule a demo

This differs on case to case basis, based on the type of installation and unique industry specific requirements. Contact us for a meeting and schedule a demo.

This differs on case to case basis, based on the type of installation and unique industry specific requirements. Contact us for a meeting and schedule a demo.

Stay Connected, follow us on LinkedIn / Twitter to know more about EAM Software latest trends.

All Rights Reserved. © Copyright 2024. Ramco Systems.