Maintenance, Repair, Overhaul (MRO) in Aviation

In a highly competitive MRO market, leaders are differentiated from the rest by their ability to achieve faster turnaround times (tat), customer satisfaction, service level compliance, on time delivery, and managing other complex business agreements.

However, MROs face many challenges, ranging from manual work scheduling, non-accurate work estimations, lack of resource visibility, inventory leakage, and disparate legacy systems. The need of the hour is to have a one-stop-shop MRO solution that enables paperless operations, manages complex contracts, and is easy to use.

Ramco MRO Aviation Solution, with 20+ years of Aviation expertise, brings the best industry practices to the users. Our solution portfolio offers the digital framework to build a scalable ecosystem for efficient MRO Operations.

The digital MRO market is projected to grow up to thrice its current market value. The key factor fueling this growth is the increasing digitalization of MRO to increase efficiency and reduce aircraft downtime. In the coming future, MRO Aviation Companies need to leverage advanced technologies such as Artificial Intelligence Aviation MRO Companies employing to coordinate, monitor, and improve all processes related to MRO, such as aircraft maintenance, repair, and overhaul.

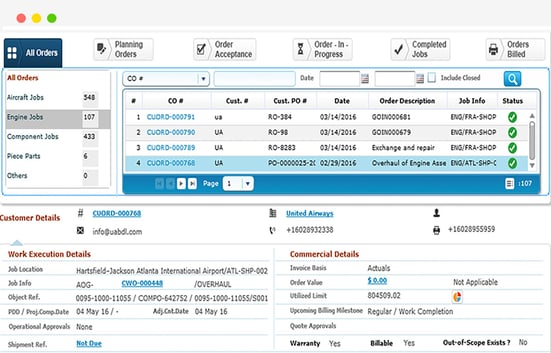

Ramco MRO Aviation Features

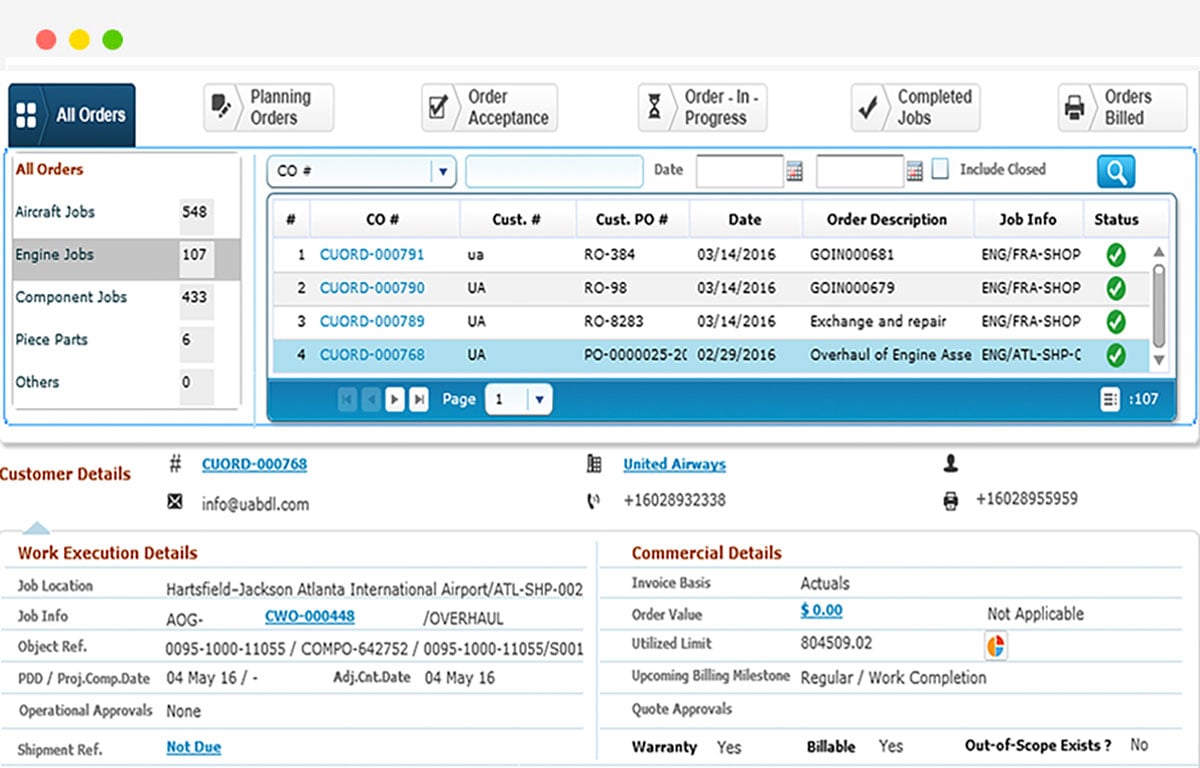

COMPONENT MRO

Standard platform enabled MRO solution comprising Component Receipt to ARC Release, Quote Management, and Invoicing processes with efficient customer interaction capabilities for enhanced operations, usability, and easy handling

ENGINE MRO

Tailored MRO solution that enables Engine slot management, Work scope evaluation, Engine visit, estimations, build-up, kitting, Digitized task card, Maintenance tracking, ARC, and Quotation & Invoicing processes with efficient customer interactions

LINE MRO

Line Maintenance MRO Solution offering AMO and Line station maintenance operations with efficient work scoping, defect reporting and flight service billing with ease

HANGAR MRO

3rd Party Aircraft Maintenance MRO Solution offering an end-to-end cycle from Aircraft Induction to Billing, Work scope Management, Task card digitization, efficient planning, connected inventory planning, and Automated invoicing functions

Why Ramco MRO Aviation Software?

ACHIEVE OPTIMIZED TAT

- Digitized contract and pricing management functions

- Automated routine and non-routine estimations

- Efficient price computations and invoicing

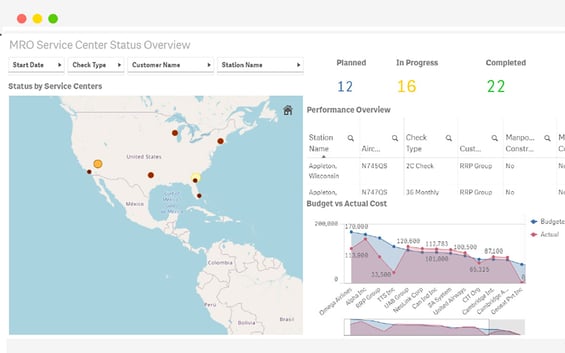

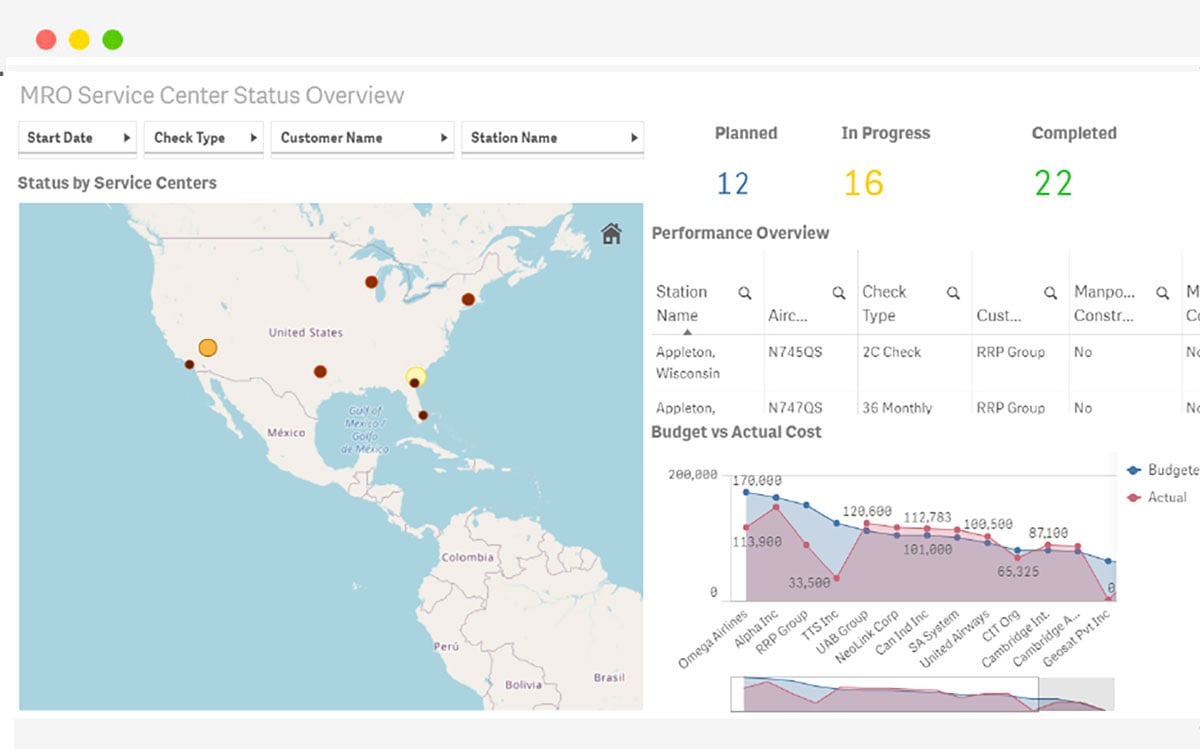

REAL TIME WORK SCHEDULING, TRACKING AND VISIBILITY

- Intuitive planning, monitoring and tracking dashboard for supervisors

- Simplified resource assignments and work prioritization

- Optimized inventory tracking and material planning

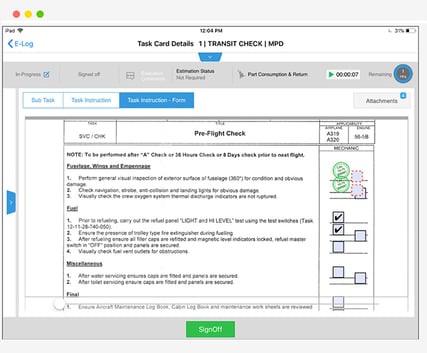

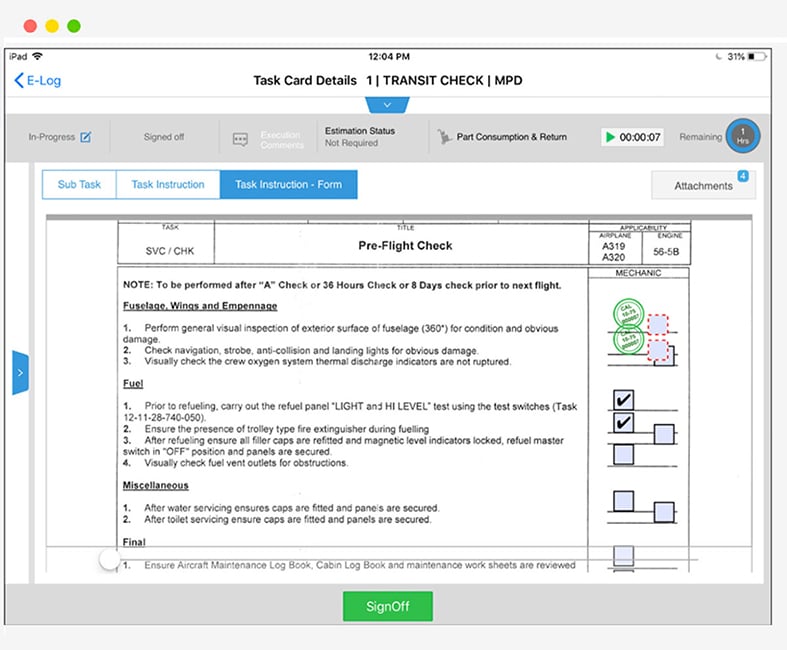

PAPERLESS MAINTENANCE OPERATIONS

- Efficient task card analysis and work scoping techniques from PDF work package

- Electronic job card attachments and digital signatures with log tracking

- User-friendly and advanced visualization dashboards

INCREASED THROUGHPUT AND REVENUE ANALYSIS

- Efficient cost analysis and pricing margins

- Best in class sales and finance functions aiding complete review of invoice tracking and customer payments

- Connected portal for customer interactions, approvals, and collaborative requests

VALUE ENABLERS WITH INDUSTRY BEST PRACTICES

- Enabling end-to-end Order to Cash Aircraft, Component MRO Services

- Established APIs with Aeroxchange, FedEx, SAP, and other 3rd party systems

- Providing a competitive edge to customers with the latest technology and market needs

- Enhanced productivity through Mobility, Chatbots, Hubs, Event-based workflow etc.

You may also like!

Whitepapers

Artificial Intelligence and Machine Learning Powered Enterprise Aviation Software

Read More