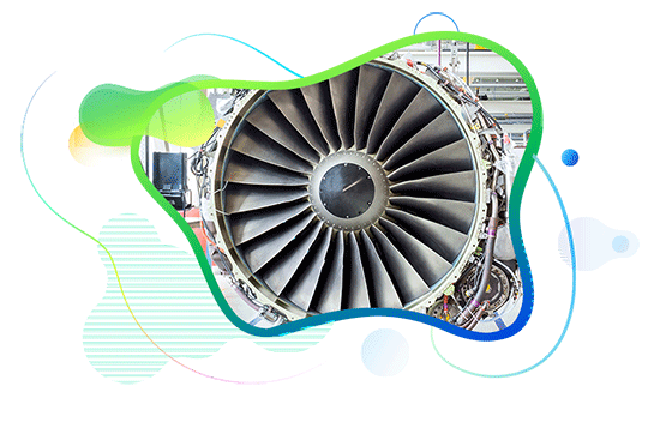

Engine MRO facilities under-take very challenging tasks, since the engine and their subsystems have to be handled very carefully during disassembly, Inspection and Assembly processes.Moreover, these facilities also need to ensure that ongoing revisions are complied with as per the OEM’s instructions.

An engine has several systems like fan modules, core, module assemblies etc. MRO Facilities require to have an understanding of which subsystem has been removed, whether existing parts are available to full-fill the demand etc. Furthermore, it is also essential to classify whether the repair for the removed components will be done internally or externally.

The complex nature of Engine MRO activities, imply that even a small mistake in any of the activities right from disassembly to assembly will have an impact on the cost and will lead to a delay on the final delivery.

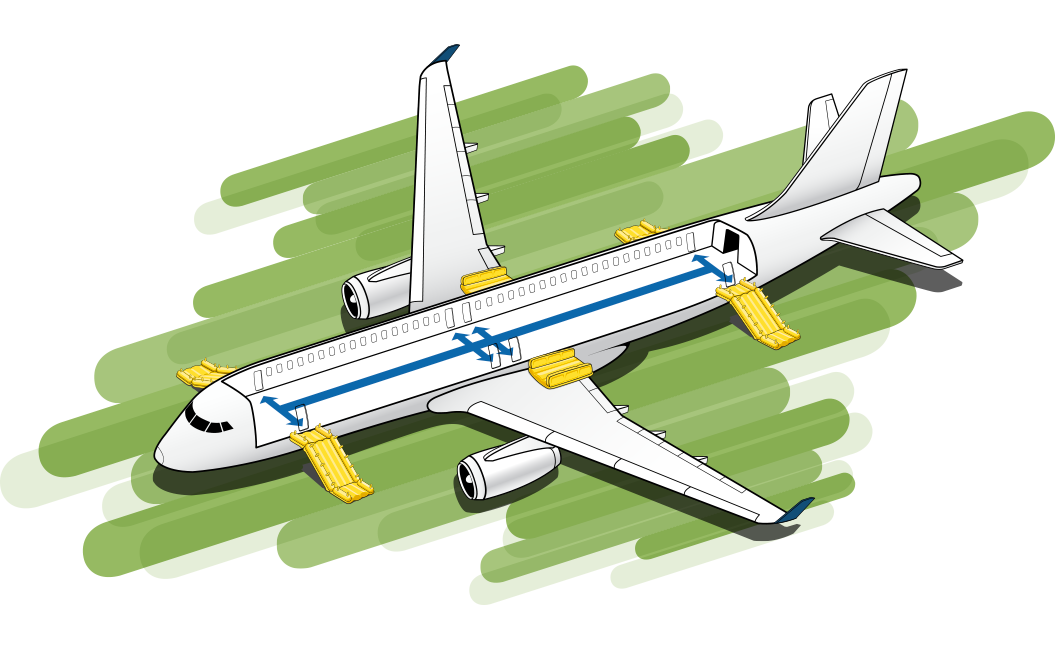

With the Engine MRO activities being critical, MRO facilities cannot afford to have certain conditions to arise during the daily activities, such as: